MBot Classic Bottom Plate Guide

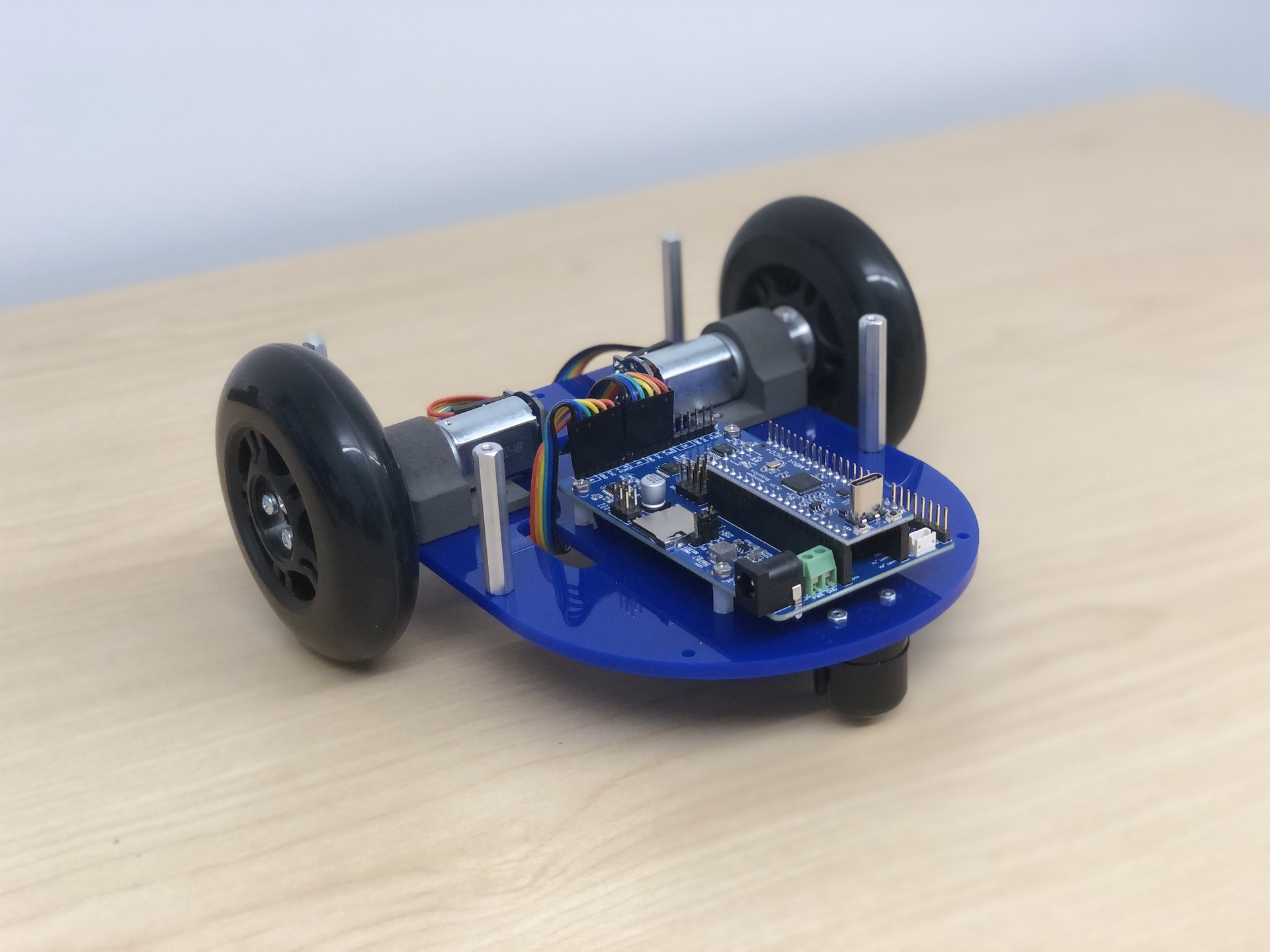

This guide is for Differential Drive MBot Classic bottom plate assembly. At the end of this guide, you should have a fully assembled bottom plate that looks like this:

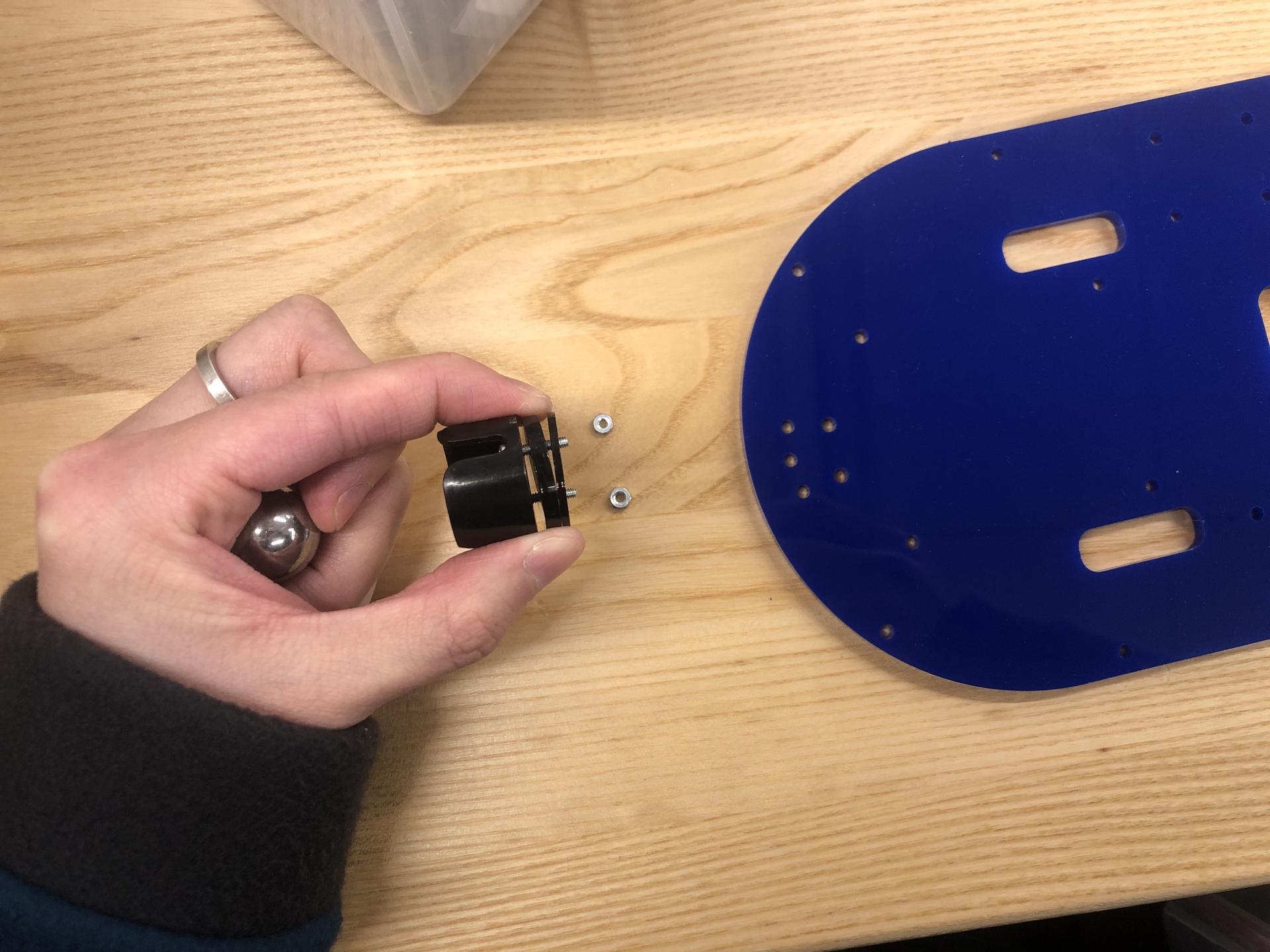

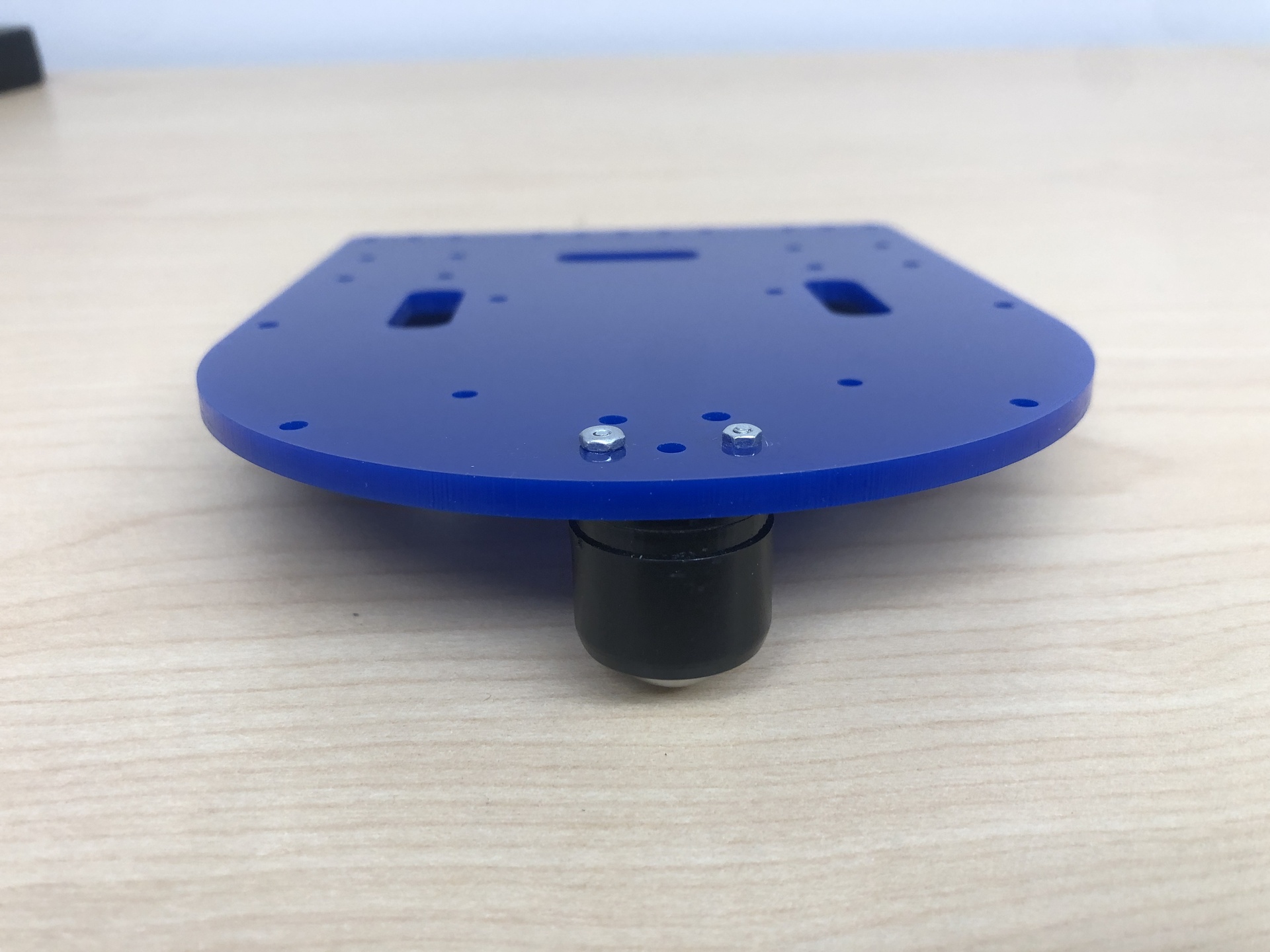

1. Mount the caster

| Components | # |

|---|---|

| Metal ball | 1 |

| Bottom Acrylic Sheet | 1 |

| 1/8” spacer | 1 |

| 1/16” spacer | 1 |

| M2 hex nuts | 2 |

| M2 x 12mm screw | 2 |

| Caster housing | 1 |

Gather all required components and assemble them as depicted in the images below. You’re not supposed to use the screws that come with the caster. Instead, search for M2 x 12mm screws to put it all together. You need to stack both spacers one on top of another during your assembly in order to match the height of the wheels.

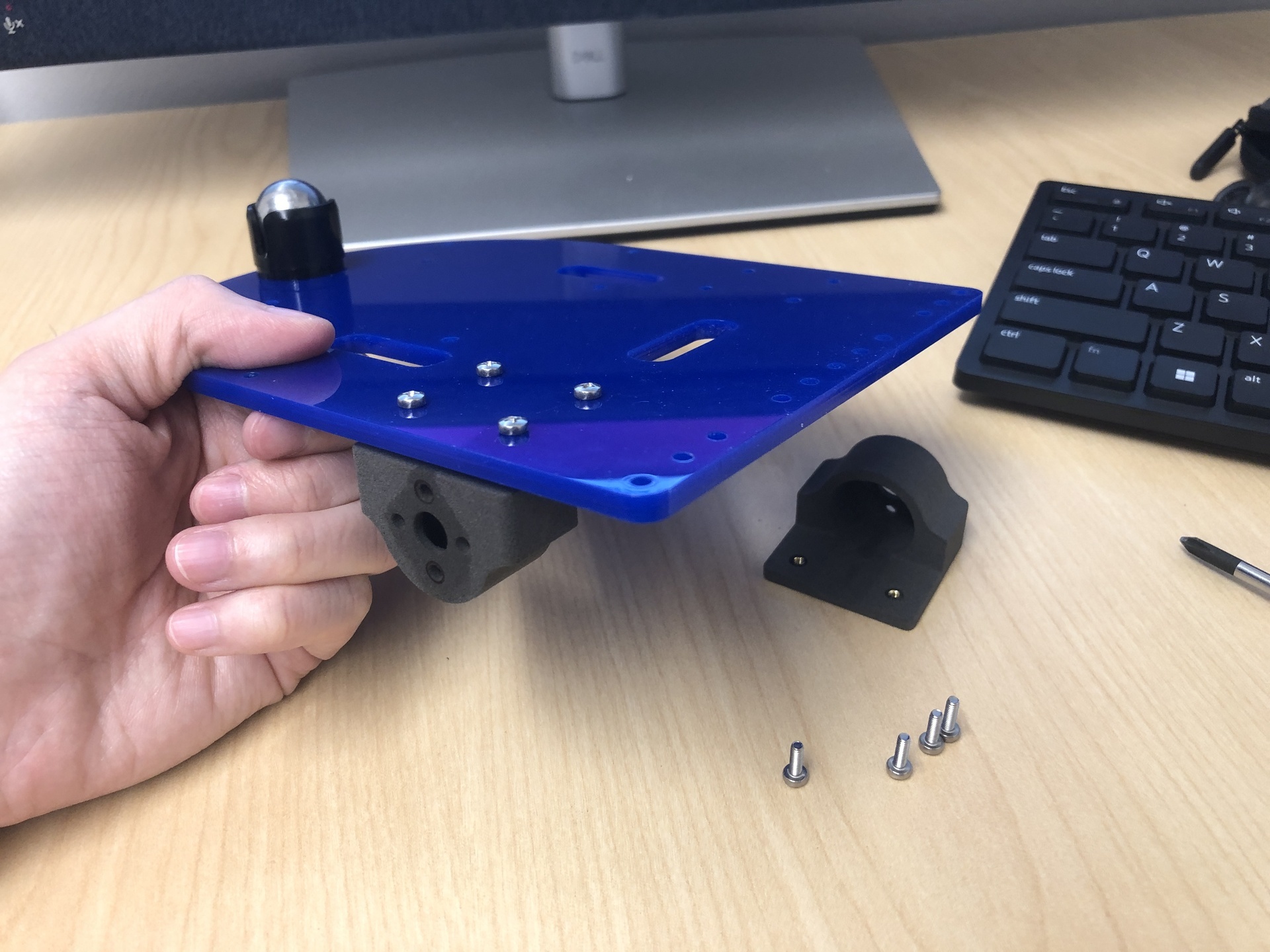

2. Mount the motor brackets

| Components | # |

|---|---|

| M2.5 x 8mm Screws | 8 |

| Motor Mount (3D printed) | 2 |

| M2.5 threaded inserts | 8 |

- If the two holes at the bottom of the motor mount don’t have threaded inserts, you’ll need to install them yourself. Here’s how:

- Heat the inserts with a soldering iron until they’re warm enough to melt into the plastic.

- Push the heated inserts into the holes until they sit flush. Allow them to cool and solidify before proceeding.

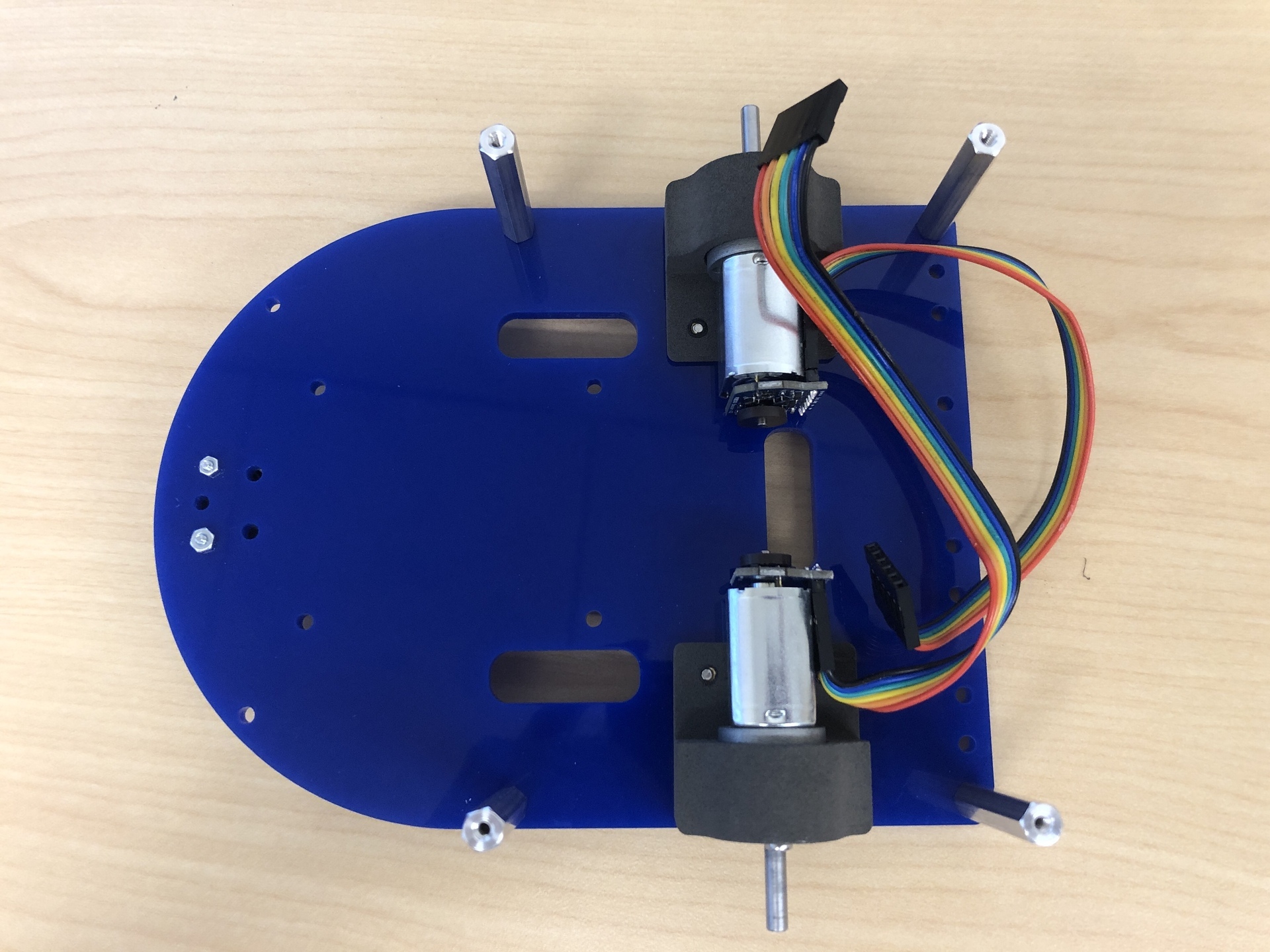

- Assemble them as illustrated in the images below. When attaching the mount to the bottom plate, ensure that the slot faces inward.

3. Mount the motors

Note: You might have encoders that are not covered in this guide. This guide covers encoders with resolution 48.

| Components | # |

|---|---|

| M2.5 x 5mm Screws | 4 |

Don’t know which encoder you are using? - Check this page

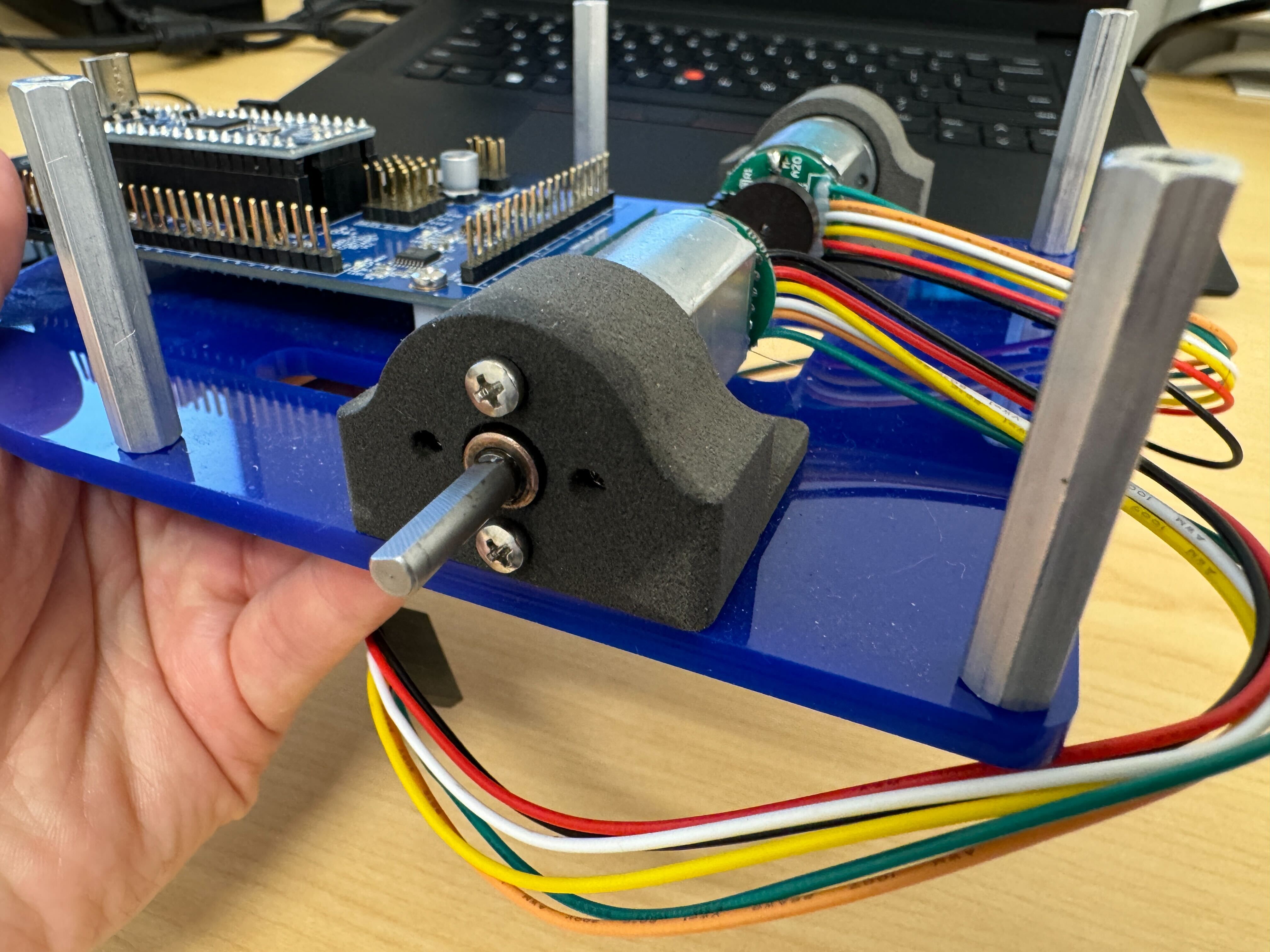

The new 48 resolution motor has encoder pre-attached. You need to align unthreaded holes in motor vertically to the holes in the motor mount, while the wires should face the back of the MBot as shown in the figure.

4. Mount the short 1.5” aluminum standoffs

| Components | # |

|---|---|

| 4-40 x 1.5inch standoffs | 4 |

| 4-40 x 3/8inch screws | 4 |

Gather all the components and assemble as shown in the images below.

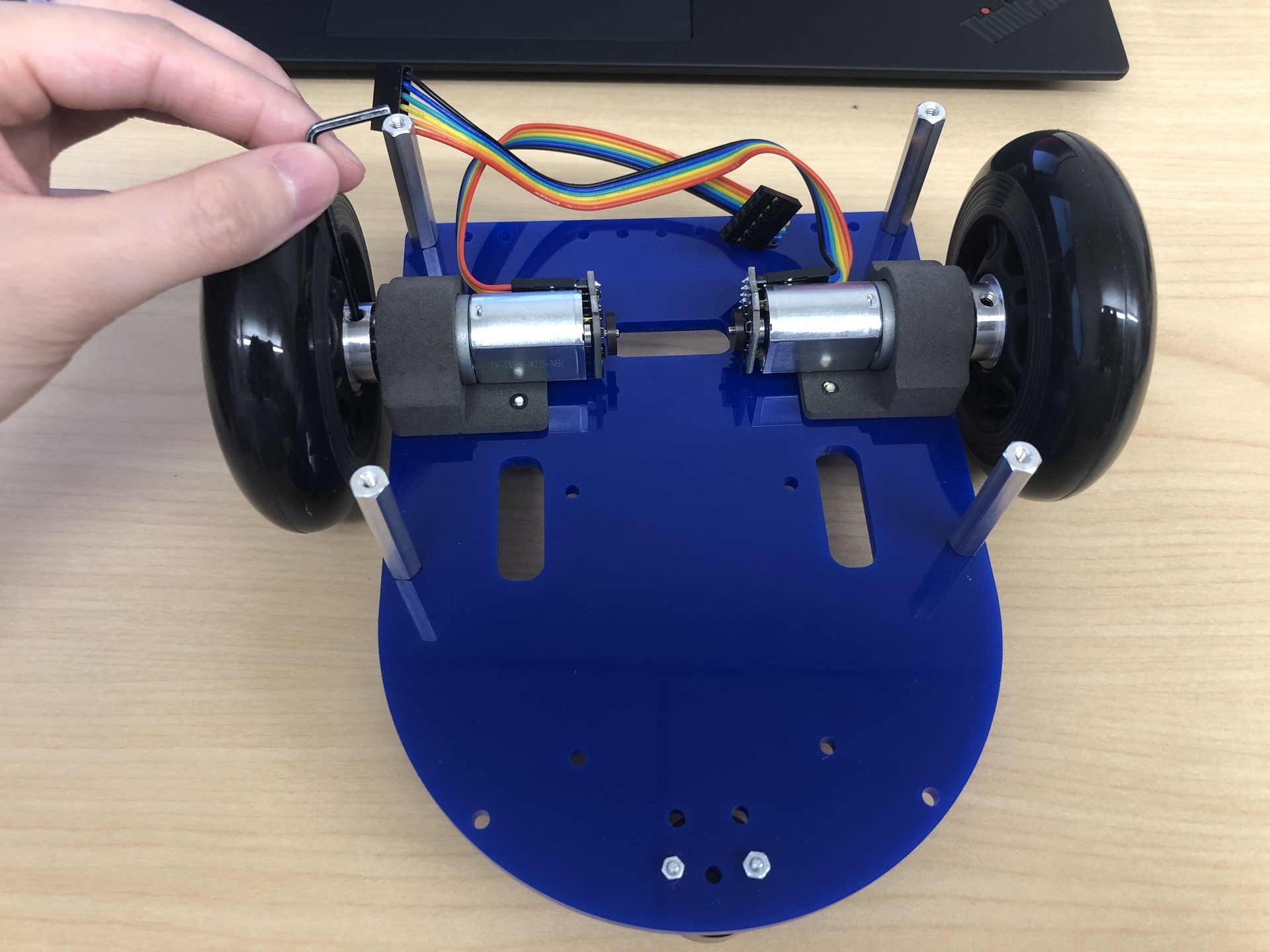

5. Attach the wheels

| Components | # |

|---|---|

| Scooter Wheels 84 X 24 mm | 2 |

| M3x20mm screws | 6 |

| Wheel adapter | 2 |

| Set screws | 2 |

| Hex Key | 1 |

Note that we will not use the M3x14mm screws that came with the wheel adaptor, as they are not long enough, instead we are going to use M3x20mm screws here.

Follow the steps below:

- First, press fit the machined wheel adaptor into one side of the wheels, ensuring a part of it sticks out.

- Then press fit the flat metal piece into the opposite side, aligning the three holes.

- Insert the M3x20mm screws to secure the parts together, as demonstrated in the second image.

- Using the 2mm Hex wrench screw the set screws that come with the wheel adaptor kit into the wheel adaptors as shown in the 3rd and 4th image.

Then you can directly put the wheel on, use the hex key to tight the wheels. Note that it is necessary to leave a bit of space between the wheel and the screw head of the motor, as depicted in the image below, otherwise the wheel hub will rub against the screws holding the motor causing excess friction or jamming the motors.

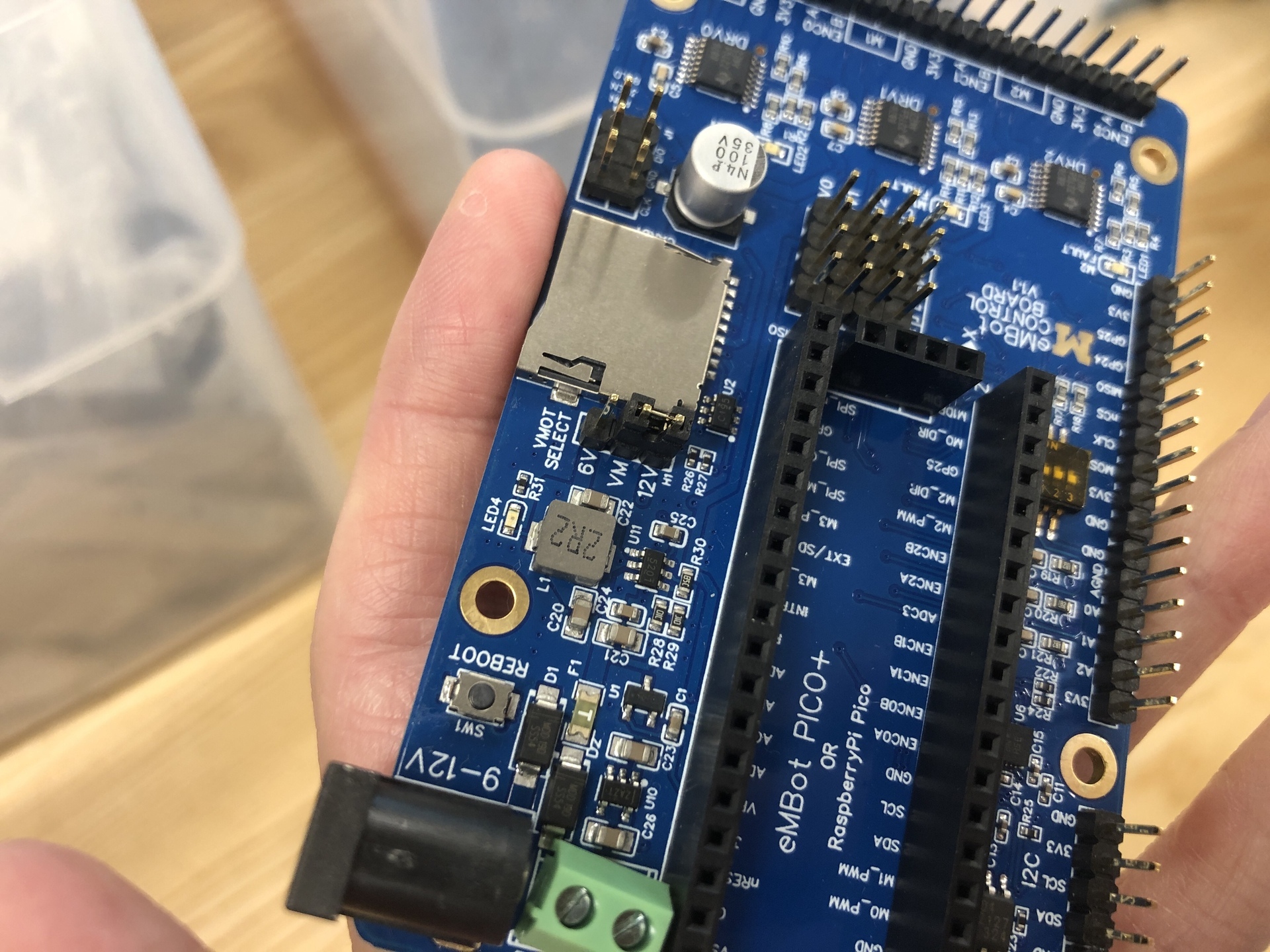

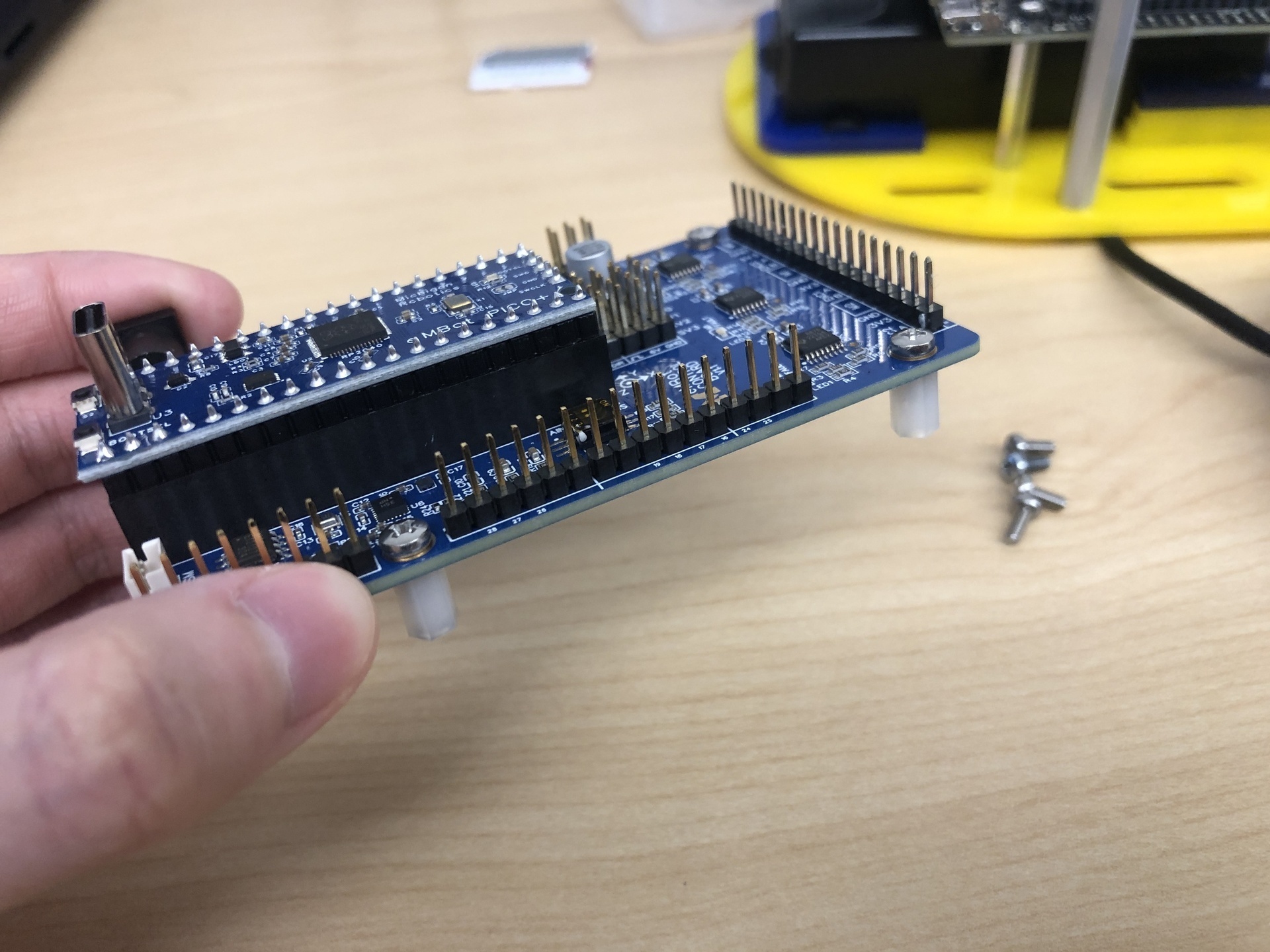

6. Assemble the Control Board

| Components | # |

|---|---|

| Robotics Control Board | 1 |

| MBot PICO+ | 1 |

| M2.5 8mm Nylon Standoffs | 4 |

| M2.5 x 6mm Screws | 4 |

| Jumper Cap (Shorting block) | 1 |

- Put the jumper cap on. Notice that in the 2nd image there are 3 pins squared together. Since we are using 12V, make sure to position the jumper cap over the VM and 12V pins, as demonstrated in the 3rd image.

- Put the Pico and the standoffs on

7. Connect the wires to Robotics Control Board.

Identify the GND pin on the Robotics Control Board and connect the wires to it accordingly. The white wire should be connected to the GND pin. Note that you should connect the left wheel to M0 slot, right wheel to M1 slot as shown in the image.

8. Attach the Control Board to the bottom plate

| Components | # |

|---|---|

| M2.5 x 6mm Screws | 4 |

Now you can move to the middle plate assembly guide!